Tornado – BHO

The Tornado hood is designed with eddy current technology and is available in several versions. The hoods work with both supply and exhaust air, creating a powerful vortex that draws in air uniformly along the entire width of the hood.

Description

The Tornado BHO hood, which utilizes eddy current technology, is used for on-site extraction of flue gases, vapors, etc. from workplaces and work processes in, for example, industries, laboratories and hospitals. BHO is available in six sizes with widths up to 3 meters and can be connected to existing exhaust air systems. The hood is equipped with one or two exhaust air connections. The Tornado hood works with both supply and extract air. The supply air taken directly from the premises is blown in through a ramp along the lower part of the hood. The design of the hood and the supply air function create a vortex movement inside the hood. The vortex – the tornado – draws in air uniformly along the entire width of the hood. The ability of the vortex to accumulate air pollutants allows the hood to withstand temporary overloads with unchanged low airflow.

Examples of uses are:

- Welding and brazing workplaces.

- Extraction over chemical baths, e.g. in surface treatment and graphic industry.

- Laboratories, where the hood can replace fume cupboards in some cases.

- Extraction over ovens etc.

- Craft rooms, woodwork rooms, laboratory rooms.

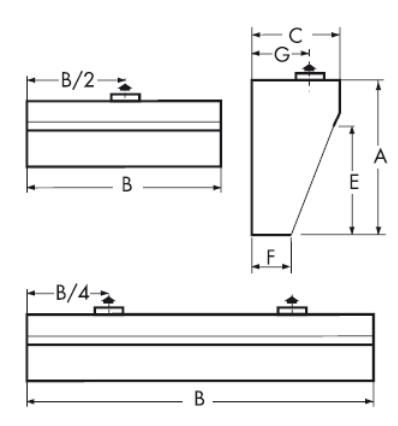

Dimensional data

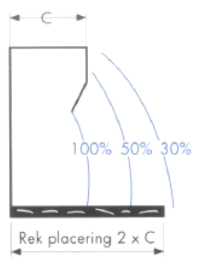

Air flow, pressure drop

The flow rate in the hood opening is crucial for the expected performance. The number of exhaust connections in the hood depends on the hood width B and the exhaust air requirement. Dimensioning and specification is done with the diagram below. Covers with widths greater than 3.0 m are combined from a number of covers.

qfrom = exhaust air flow rate m3/s (m3/h)

Pt = total pressure drop Pa (mm vp)

Example

Cabinet width = 1.4 m

Cabinet size = 3

Exhaust air flow 0.4 m3/s

Pressure drop = 52 Pa with 1 connection

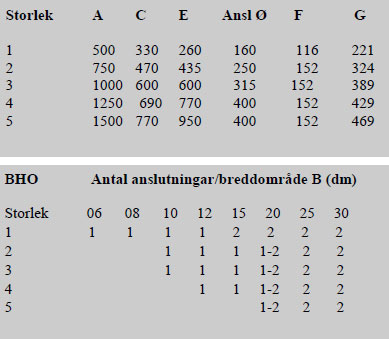

Catchment area

The figure shows the decreasing inflow velocity in front of the Tornado cover. The curves show points of equal velocity (isovelets) as a percentage of the design inflow velocity through the hood opening.

Design instructions

When evacuating from a workbench, the depth of the enclosure, Cmeasurement according to the dimensional drawing, should be at least half the depth of the table. The height of the free opening of the enclosure, E, shall exceed the height of the object being handled on the table.

Lighting

Special work lighting at the Tornado enclosure is best organized locally. For flow reasons, large fluorescent luminaires cannot be placed inside the enclosure. The most suitable location for such luminaires is at the front of the enclosure. However, smaller and simpler recessed luminaires can be installed in the enclosure if the surrounding environment allows it.

Explosion-proof design

If the room where the Tornado hood is to be installed is classified as explosion-proof, the standard fan built into the hood must be changed to the EEX eIIT3 version. In this version, the fan has significantly larger dimensions and capacity and must therefore be mounted outside the hood and, when adjusting, be throttled down to the required supply air flow. Alternatively, up to five hoods can be connected to one fan.

Specification

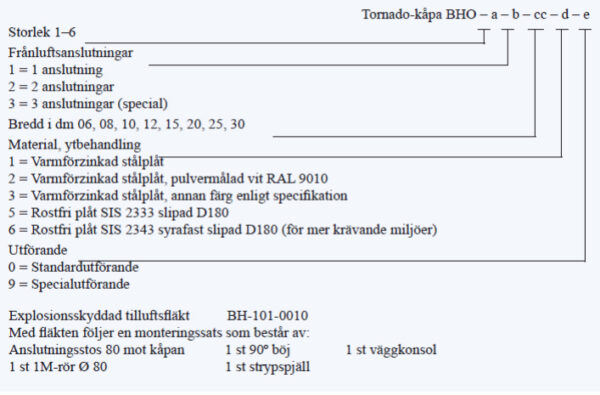

Tornado hood BHO of Tovenco’s make in size e.g. 3, with 2 exhaust air connections and a width of 15 dm. The hood shall be made of hot-dip galvanized sheet steel and painted white.

Order example

We are professionals in commercial kitchens and will help you find the right one.

Book a meeting to discuss your needs.